Deanprint Ltd – The First 125 Years

The history of Deanprint Ltd can be traced back to a young entrepreneur named Joseph Dean. Joseph was a Yorkshireman who despite being born into impoverished circumstances, used his intellect and determination to set up a travel agency – Dean & Dawson – in 1871.

Joseph eventually bought a printing press as he recognised the potential of being able to produce his own brochures for the travel company. This simple acquisition lead him to establish, in 1890, the company that still bears his name today.

The printing business steadily grew and soon a second factory was required. This was half a mile away from the first. During this period Mr Dean became friendly with one of the pillars of Stockport’s hatting industry – Mr Giles Atherton. Together they went to America and while in New York they were offered the patent rights to hat leather stitching machines. From this the company also began making hat leathers and a wide variety of other leathers. This business was run from a third factory in Stockport. It soon became obvious that the company should acquire more suitable premises. Two of the factories were sold which enabled land to be bought and in 1920 building work commenced on a new 47,000 sq. ft. factory without having to borrow any money. The total cost of this factory was £21,000.

Some photos from the 1930s

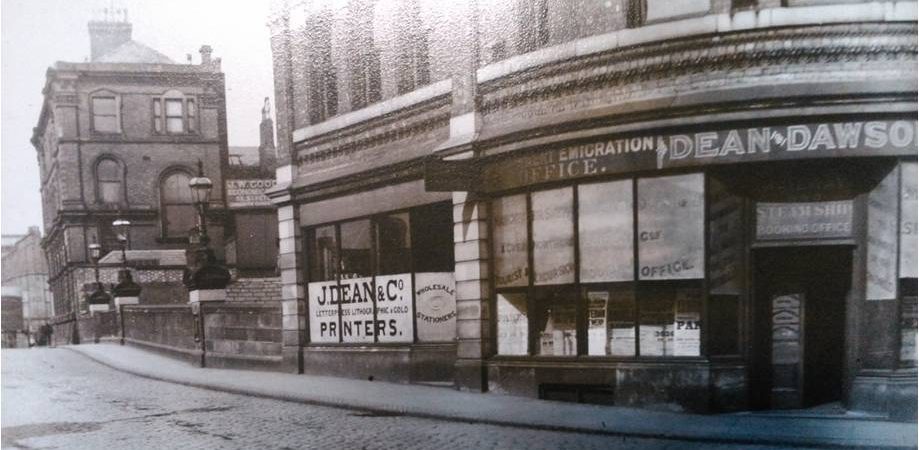

- This photo was taken in the 1890s of the Dean & Dawson Travel Agency, with the newly established printing company on the left

Today the company still operates from this factory. At it’s peak there were over 120 employees and there was an office in London. Now there are 45 members of staff and 110 printing and finishing machines. The current Directors succeeded in a Management Buyout in 2011 and since then the company has invested heavily in more than a dozen machines and in new systems, has recently introduced a shift system and is running more profitably that any time in the last thirty years.

The broad range of services that we offer – printing, case binding, perfect binding, wiro-binding, singer sewing, ringbinders, slipcases, boxes, folders, etc. – offer our customers a wide range of options with the confidence that everything is done in-house.

The staff are fully behind the many changes as they understand that long-term sustainability is a prime objective. The company is building a very solid base which we hope will stand us in good stead as we enter the next phase in our history.